Introduction

The fundamental goal of a transdermal medication delivery system is to deliver pharmaceuticals into the systemic circulation through the skin at a predefined pace with little fluctuation between and within patients. The most significant advantages provided by the following are some examples of transdermal medication delivery: increased bioavailability and effect duration, resulting in a reduced dosing frequency, plasma levels are more uniform, and adverse effects are reduced. Transdermal patches are a type of patch that is applied to the skin. It's proved helpful in minimising the effects of first-pass medication degradation.1 Transderm SCOP was the first transdermal patch to be approved for the prevention of nausea and vomiting. In 1979, the Food and Drug Administration (FDA) identified travel as a risk factor. The majority of transdermal patches are made to release the active ingredient. For several hours to days following application to the skin, the chemical has a zero-order rate. Drugs penetrate multiple layers of skin and permeate the epidermis into systemic circulation in transdermal patches.2

Some substances, such as dimethylsulfoxide, azones, pyrrolidones, urea, and fatty acids, can improve medication penetration through the skin. In general, once medication molecules break the stratum corneal barrier, they move swiftly and easily into deeper dermal layers, allowing for systemic uptake. Glimepiride is a sulphonylurea-class oral antidiabetic medication with a medium to long half-life.3 It is a sulfonylurea of the second generation that is used to treat type 2 diabetes. It causes a rapid release of insulin from pancreatic beta cells by inhibiting ATP-sensitive k+ channels, which causes depolarization and Ca2+ influx sensitivity.

Materials and Methods

Materials

Glimepride was received as a gift sample from micro labs Pharmaceutical Ltd., Hosur Tamilnadu. Methyl cellulose was obtained from spectrum reagents and chmicals Pvt. Ltd., Edayar, Cochin. PVP K30 was obtained from oxford lab fine—Chem. Ltd, Maharashtra. Polyethylene glycol 400 was obtained from Indian Research Product, Chennai. Tween-20 was obtained from Isochem Lab Angamaly, Kochi.4 Chloroform and methanol was obtained from Isochem Lab Kanjikoda, Palakkad. All other materials and chemicals used were of either pharmaceutical or analytical grade.

Methods

Matrix type transdermal patches containing Glimepiride were prepared by solvent evaporation technique. Overall three batches were formulated using different ratios of MC and PVPK30. Casting solution was prepared by dissolving weighed quantities of polymer PVPK30 and MC (total weight of polymers were kept 500 mg), and plasticizer (36% w/w of polymers) and penetration enhancer (12% w/w of polymers) in an appropriate solvent system. The base of the ring was wrapped with aluminum foil.5 A glass bangle as a mould was placed in the petridish above the aluminum foil. A fixed volume (5ml) of polymeric solution with drug and plasticizer was poured on to the petridish and inverted funnel was placed on the petridish to facilitate the evaporation of solvent at a controlled rate over the drying period of 24 h at room temperature. The dried film were removed and cut into 2 cm area and kept in a desiccator further used.6

Table 0

Total polymeric weight: 500 mgDensity of PEG400 =1.13 therefore, Amount used 0.180 ml Plasticizer = (36% w/w total polymeric weight)Density of tween 20 is 1.095 g/mL therefore amount used 0.06 ml penetration enhancer =(12% w/w of total polymeric weight)

Preliminary studies

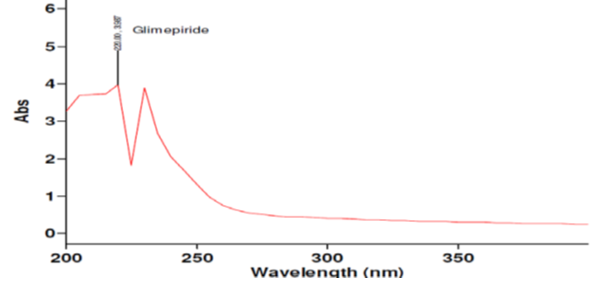

Determination of λmax

Glimepiride 10mg was precisely weighed and first dissolved in 35ml methanol solutions. These solutions were then diluted to 100 ml with phosphate-buffer pH-7.4 solution. The UV spectrum was captured at wavelengths ranging from 200 to 400nm.7

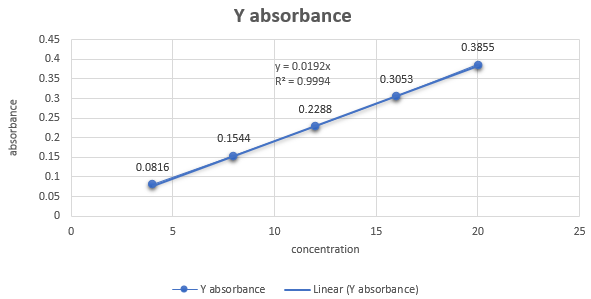

Preparation of calibration curve for glimepiride

The phosphate buffer pH 7.4 media was used for concentration. The absorbance at 228 nm wavelength was measured spectrophotometrically. Table 2 shows the absorbance value. Figure no shows standard calibration curves with a slope of 0.0192 and a regression coefficient of 0.9994. The curve was found to be linear in the range 2-12 µg/ml when a drug solution of 50 µg/ml was prepared. 4,8,12,16,20µg/ml dilutions.8

Evaluation of transdermal patches

Physical appearance

Color, Non Transeparancy, softness, and elasticity of the formulated films were evaluated.

Thickness

Vernier callipers were used to fine-tune it. After measuring the thickness of the patch at five different locations, three readings were taken for standard deviation. The thickness of Glimepiride patches ranged from 102.32 to 115.56 m.

Weight variation test

Initially, three patches were chosen at random from all batches, and three films were chosen and weighed separately from each formulation, with the mean for weight variation test and standard weight estimated.9 The weight of Glimepiride patches ranged from 106 to 143 mg.

Folding endurance

Patch folding endurance was found to be satisfactory between 90.31

Flateness

The films were cut longitudinally from formulated patches, and the lengths of individual films were calculated. The length difference caused by non-uniformity in flatness was measured. It was calculated by measuring the constraint of films, with zero percent constraint equaling one hundred percent flatness.11

Where,

Moisture absorption study

The films were exactly weighed accurately in desiccators containing 100 ml of saturated aluminium chloride solution (79.50 percent RH). After three days, the films were removed and weighed; the percentage of moisture absorption was determined by the difference between both the final and initial weights in relation to the initial weight.12

The moisture absorption in the formulations is ranged from 1.09±0.20% to 5.47±0.45% (for

formulation F series respectively)

Moisture content

The patches were weighed and placed in a calcium chloride-containing desiccator at 40o C for 24 hours. When there was no further change in the weight of the patch, the final weight was recorded. The moisture content percentage was calculated as the difference between the initial and final weights in relation to the initial weight.13

The moisture content in the patches was ranged from 1.03 ± 0.12% to 2.26 ± 0.54% (for formulation F series and formulation respectively)

Tensile strength

The instrument was built with a horizontal wooden platform with a fixed scale and attachments for two clips that hold the transdermal patch under test. One clip was fixed and the other was movable. Weights were hung from one end of the pulley, and the other end was secured with a movable clip. The wooden platform was so well-fitting that it would not move during the test. Three patch strips with a length of 4 cm and a width of 0.5 cm were cut. The thickness and breadth of the strips were measured at their respective locations, and an average value was calculated. Ink was used to mark 2 cm apart and 1 cm at each end of the strips. Each strip was clipped together in such a way that the markings were barely visible. The instrument maintained a constant rate of change of stress of 0.5 gm per 2 minutes. The elongation was measured, and the total weights were computed. Tensile strength was determined using.

Weight variation and drug content

The weight of Glimepiride patches ranged from 106 to 143 mg. This demonstrated uniformity in patch weight, while the percent drug content of Glimepiride in patches ranged from 90.03 to 90.43 ±0.91 percent, indicating passable drug content in patches.

In-vitro drug release study

The Franz diffusion cell consists of an upper donor compartment and a lower receptor compartment surrounded by a water jacket to keep the receptor phase at 32 ± 1℃ (USP). The uniformity of the solution in the receptor phase was maintained by stirring at a speed of 600 rpm (approx.) with a tiny Teflon coated magnetic bead. The receptor compartment was kept at a volume of 60ml. The receptor compartment was equipped with a sampling port on one side to allow for the withdrawal of samples at predetermined time intervals for drug content estimation using a UV spectrophotometer. The receptor medium was phosphate buffer saline (PBS) pH 7.4 with 30% v/v PEG-400 as a solubilizer.

Permeation studies

The dorsal skin of a rat was removed. A sharp scissors was used to remove the hair and underlying tissues. The skin was properly cleansed using purified water and regular saline. Before use, it was soaked overnight in regular saline and rinsed numerous times. The skin was then sliced to size and put between the diffusion cell sections, with the stratum corneum facing the donor compartment. It was kept on the receptor fluid overnight to stabilise and optimise it. The matrix formulation was cut into 1cm to 2cm patches (n = 3) and placed on top of the optimised skin. The occlusive backing was then coated with aluminium foil. With the use of springs, the donor compartment was clamped over it, ensuring that there were no air bubbles in the receptor chamber. 3mL samples were taken at preset intervals up to 48 hours. To maintain a constant volume, new receptor fluid was supplied to the receiver compartment. After that, the filtered samples were examined with a UV double beam spectrophotometer (Schimadzu) at 220nm maximum. From 4 to 20 g/ml, linearity was demonstrated (R2 > 0.994).

Result and Discussion

Evaluation of transdermal film

Table 1

Physical appearance of TD batch F1 to F3

Table 2

Thickness of TD batch F1 to F3

|

Formulation |

Thickness

|

|

F1 |

102.32±1.05 |

|

F2 |

107.44±1.11 |

|

F3 |

115.56±1.21 |

Table 3

Folding endurance,Flatness, Tensile strength of TD batch F1 to F3

|

Formulation |

Parameters |

||

|

Folding Endurance |

Flatness |

Tensile Strength kg∕mm2 |

|

|

F1 |

90.31±2.16 |

100% |

0.21±0.043 |

|

F2 |

95.76±1.03 |

100% |

1.04±0.560 |

|

F3 |

101.51±0.34 |

100% |

1.74±0.676 |

Table 4

Moisture content and moisture absorption studies of TD batch F1 to F3

|

Formulation |

Moisture content |

Moisture absorption |

|

F1 |

1.03±0.12% |

1.09±0.20% |

|

F2 |

1.27±0.36% |

2.76±0.23% |

|

F3 |

2.26±0.54% |

5.47±0.45% |

Table 5

Weight variation and drug content

|

Formulation |

Parameters |

|

|

Average weight (Mg) |

%Drug content |

|

|

F1 |

106.23±1.76 |

90.03±0.56 |

|

F2 |

125.34±2.06 |

89.76±0.51 |

|

F3 |

143.68±3.17 |

90.43±0.91 |

Table 6

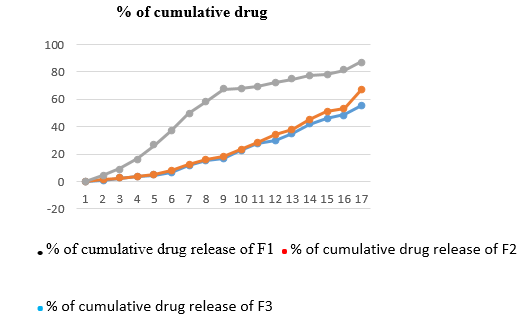

In-vitro skin permeation study

Conclusion

The concentration of Methyl cellulose when increased into primary layer In Vitro diffusion rates were also increased and also as concentration of PVP when inceased, the drug diffuson rate was decreased and vice versa. Batch F3 was the optimized formulation showing uniform thickness, good tensile strength, drug content uniformity and good folding endurane. The formulation F3 showed linear zero order release for 24 hours with cumulative % drug diffused of 87.35% from 4 cm2 patch of batch F3.

Acknowledgment

Glimepride was received as a gift sample from micro labs Pharmaceutical Ltd., Hosur Tamilnadu. Methyl cellulose was obtained from spectrum reagents and chmicals Pvt. Ltd., Edayar, Cochin. PVP K30 was obtained from oxford lab fine—Chem. Ltd, Maharashtra. Polyethylene glycol 400 was obtained from Indian Research Product ,Chennai. Tween-20 was obtained from Isochem Lab Angamaly, Kochi. Chloroform and methanol was obtained from Isochem Lab Kanjikoda, Palakkad.