Introduction

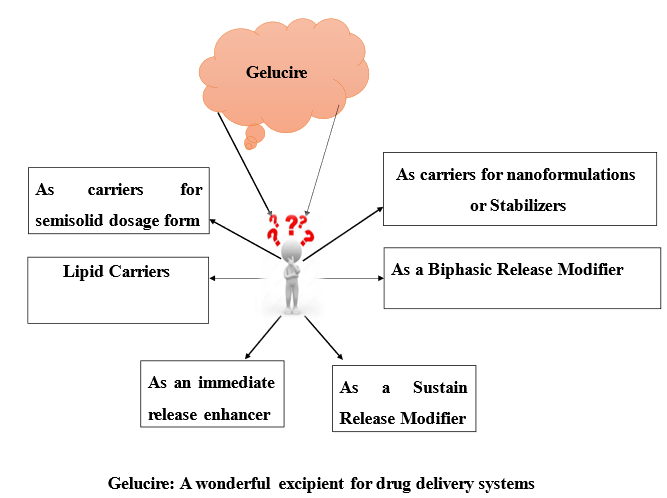

Gelucires are a group of lipid-based excipients made up of glycerides and polyethylene glycol esters, which impart both hydrophobic and hydrophilic characteristics to the formulation. Gelucire is utilized to improve the physicochemical properties of drugs and serve as a matrix for controlled release formulations. Here are some important applications of Gelucire in drug delivery designing.

Applications

As lipid carriers

Gelucire is the most used lipid carrier for the preparation of SDD of poorly water-soluble drugs. Gelucire grades differ based on their HLB value, ranging from 1 to 18, and melting point, 33–70 °C. HLB values govern the mechanism of drug release. The fundamental characteristics of Gelucireconsist of the amphiphilic self-assembly characteristics, which means it helps to form fine dispersion of the lipid moiety in the presence of aqueous media.1

As an immediate release enhancer

Different grades of monolithic Glucire are used in immediate release formulations and while applying granulation, spray drying, or melt granulation techniques with an optimized amount of disintegrating agent can promote almost complete release of the drug within a few minutes.2, 3

As a sustain release modifier

Gelucire containing glycerides or a mixture of glycerides and PEG esters are extremely hydrophobic and very low in density; thus, they are appropriate for sustaining the release of the drug from its delivery systems.4

As a biphasic release modifier

Modification of the release profile by means of biphasic delivery can be achieved by using two different grades of gelucire. PEG ester containing Gelucire (50/13) is a rapidly dissolving excipient with hydrophilic nature, whereas only glycerides or mixtures of glycerides and PEG esters containing Gelucire (43/01) are highly hydrophobic and suitable for sustained release preparation. The combination together can provide a loading dose (by immediate release) and maintenance dose (by sustained release) in the form of solid oral dosage of the drug molecules.5

As carriers for semisolid dosage form

The Gelucire group of excipients is also widely applied in semi-solid surfactants and matrix formers, which helps in solubility and bioavailability enhancement in lipid-based formulations. Gelucire 48/16 (water-soluble) and Gelucire 44/14 and 50/13 (water-dispersible) variants are mostly used in the semisolid preparation, which shows distinct melting points and HLB values suited for diverse pharmaceutical applications.6

As carriers for nano formulations

Gelucire 44/14, with self-emulsifying properties, is used as a nanocarrier system to enhance drug solubility, bioavailability, and stability of the self-nano-emulsification system. Its thermoplasticity supports applications in melt-based drug delivery techniques.7

As a stabilizer

Gelucire 50/13 serves as an effective stabilizer for lipid nanocarriers like solid-lipid nanoparticles and nanostructured lipid carriers, enhancing drug loading for hydrophobic drugs. Its bioavailability-boosting properties and compatibility with nanoscale formulations provide significant therapeutic advantages.8, 9

Conclusions

Gelucire is used in advanced drug delivery design like in 3D printing technology, demonstrating its versatility as a lipid-based excipient, enabling the fabrication of complex drug delivery systems. The thixotropic properties of gelucire and its compatibility with pharmaceutical semi-solid extrusion and pressure-assisted microsyringe techniques facilitate the development of customizable, patient-specific formulations with enhanced drug solubility and controlled release profiles. 9